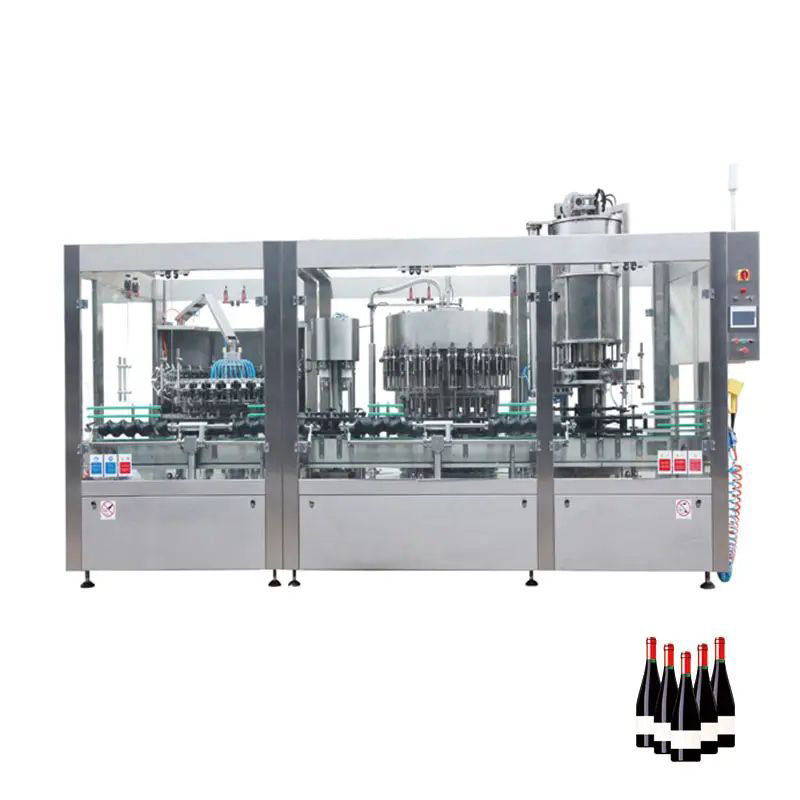

Wine Washing Filling Capping Machine especially design to fill spirit and wine into glass bottle, the process chart is below:

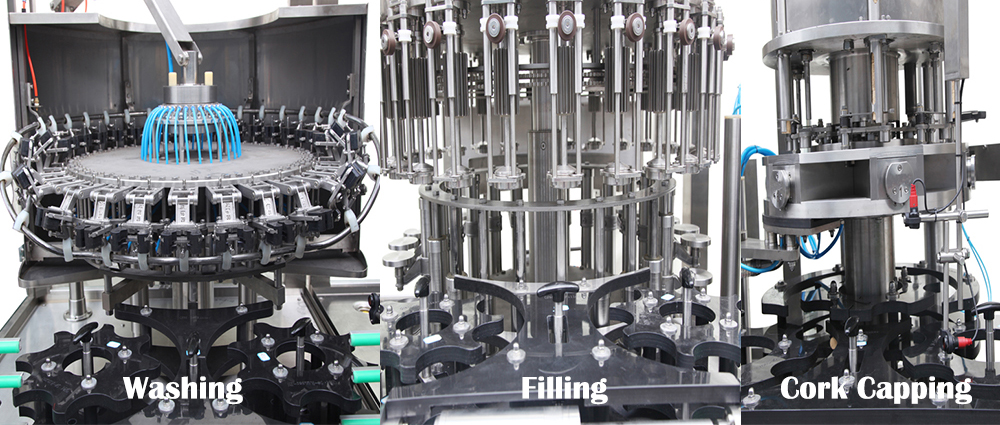

Rinse the empty bottle with clean water — filling wine into the glass bottle — capping the filled bottles with corks. It is a 3 in 1 filling machine.

Automatic 3 in 1 Wine Filling Machine

Features:

1. High efficiency: frequency conversion speed regulation, production capacity can reach 1000-20000 bottles/hour.

2. Large range: applicable to bottle diameters of 60-100mm, bottle heights of 220-350mm, filling volume of 50-1500ml, wide application range and convenient adjustment.

3. Fully compatible: all kinds of round containers such as glass, porcelain, plastic and ceramic bottles can be fully automated. This machine can be easily connected with various original bottle conveying lines.

4. Liquid level: The filling accuracy liquid level is +2 mm, which is better than the industry standard.

5. No dripping: The seal is tight and reliable, the bottle is broken, leaked, and no bottle is automatically not filled, and no liquid is spilled.

6. No bottle break: automatic adaptation to bottle height error, frequency conversion speed regulation, soft start, soft brake, no rigid impact, overload protection in the process of bottle feeding and stoppering, no bottle breaking and machine damage.

7. The filling machine is equipped with a bottle feeding and unscrambler, which makes the bottle feeding more stable.

8. No bottle or stopper: prevent the waste of cork.

Parameters:

| Items | Parameters |

| Washing head | 12 |

| Filling head | 9 |

| Capping head | 1 |

| Production capacity | 1000BPH@750ml |

| Air source pressure | 0.5-0.6MPa |

| Rinsing water pressure | 0.15-0.2 MPa |

| Bottle height | 150-340MM |

| Bottle diameter | Φ50-Φ110MM |

| Power | 3ph, 380V/50Hz,2.2KW |

| Weight | 2000Kg |

Details

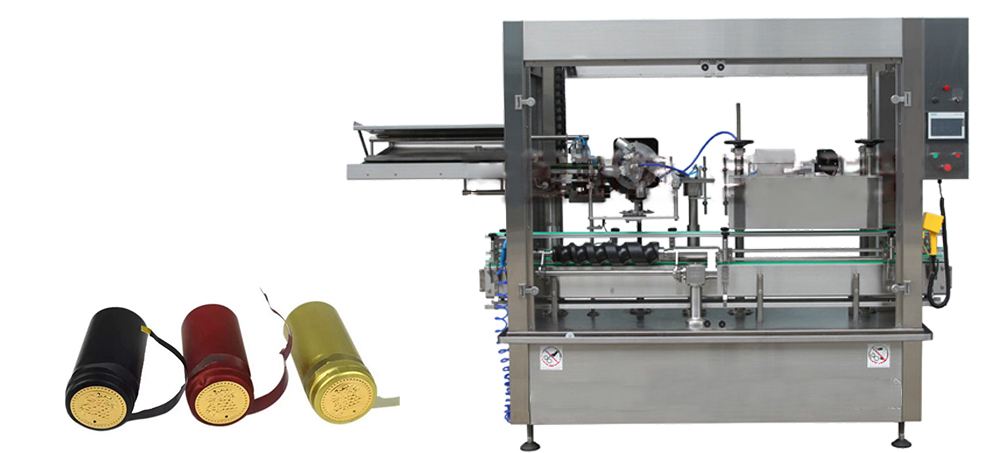

Related Products