Lube Oil Filling Machines - Revolutionizing Industrial ...

Hi, I am Anita, General Manager of GSS and an expert in the liquid chemical filling machine industry for over 20 years, I wish to share my experience in the field.GSS is a leading liquid chemical filling machinery manufacturer, We can provide you with a one-stop OEM/ODM solution for all your 0-2500L liquid chemical filling equipment requirements.

Engine / Motor Oil Filling Machine: The Selection Guide

1.1 The engine oil filling machine is servo driven, the filling volume is Volumtic by piston type, it is most popular filling machine using in industry oil fields. 1.2 It is handling with oil industry standard, Number of filling nozzles are range from 2 to 16 heads to meet for different capacity needs; Handling engine oil density @30°C to 35 ...

A Comprehensive Guide to Lube Oil Filling Machines

Discover everything you need to know about lube oil filling machines, including their features, benefits, and applications. Learn how these machines work and how they can streamline your oil filling process. Find the best lube oil filling machine for your needs and optimize your production efficiency. Click here for the ultimate guide.

Engine Oil Filling Machines: Precision in Automotive ...

Precision Filling: Automatic engine oil filling machines are equipped with precise measurement mechanisms, ensuring accurate dispensing of the desired volume into each container. 2. Efficiency and Speed: Automation enhances production efficiency and speed, surpassing the capabilities of manual filling methods.

2 Nozzle Liquid Filling Machine - VKPAK

High speed—40-50 bottles/min with only 2 filling nozzles; Wide Application— fast switching for various bottles and products; Easy but High Clean—rotor pump control, CIP cleaning optional; Touch screen operation interface; Support up and down movement type filling to effectively prevent foam generation

Lubricants Filling Machines: Revolutionizing Industrial ...

Lubricants filling machines have embraced innovations like programmable logic controllers (PLCs), touch screen interfaces, and automation technologies. These advancements streamline the filling process, enhance accuracy, and reduce manual intervention. Efficiency and Modern Technology The integration of modern technology translates into higher ...

LUBRICANT OIL FILLING LINE | OIL Filling Machine | Linus ...

Linus Projects takes pride in delivering a Lube Oil Filling Machine that accommodates a wide range of filling capacities. From 250 ml to 5 liters and 2 liters to 25 liters, this machine offers unparalleled versatility to meet the varying needs of the Lube Oil and Grease industry.

Lubricant Oil filling machine - Lube Oil packaging machine

Machpack offers the Semi-Automatic and Automatic filling machines models suitable to all type of lubricant oil and all types of bottles, containers and cans. +91-9978905051 info@machpackprocess Facebook

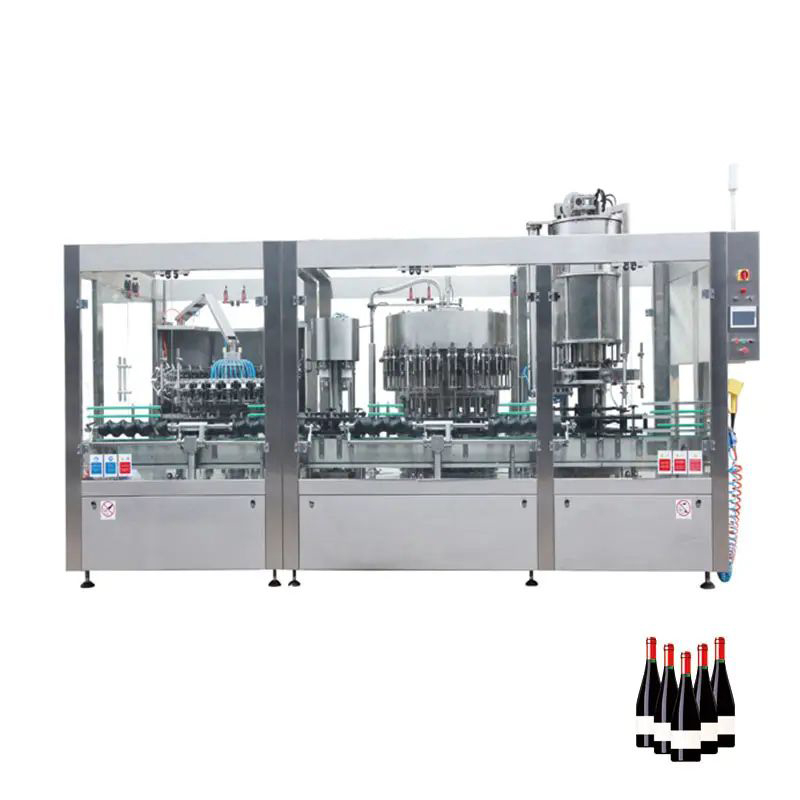

Full Automatic Lube Oil Filling Machine - TopFillers

Numbers of filling nozzles: 2-12 filling nozzles for optional. Filling size: 50-200ml, 100ml-1000ml and 1000ml-5000ml. Standard power: 220V, 50/60HZ, single phase or 380V, 50/60Hz. Dimension and weight: subject to the model configuration and customer products. Quick Details

Twelve Nozzle Automatic Lubricant Oil Filling Machine (Piston ...

1. Servo driven piston for accurate filling quality. 2. Pneumatic shut-off nozzle prevents liquid from dripping down. 3. Nozzle spacing and height is adjusted by top hand wheel and screw. 4. Available for bottom up filling for foamy liquid. 5.

Contact Us Now