This Shrink Sleeve Labeling Machine is used for pet bottle or glass bottle with shrink label, the labeling position is at the middle body of the bottle or full covered from the top/neck to the bottom of bottle, which is widely used in water/juice/beverage production.

Bottled Water Shrink Sleeve Labeling Machine

Features:

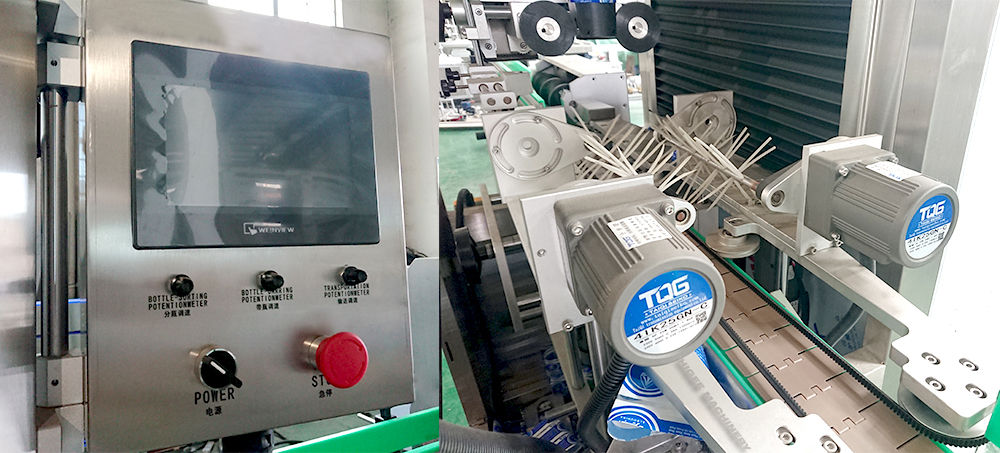

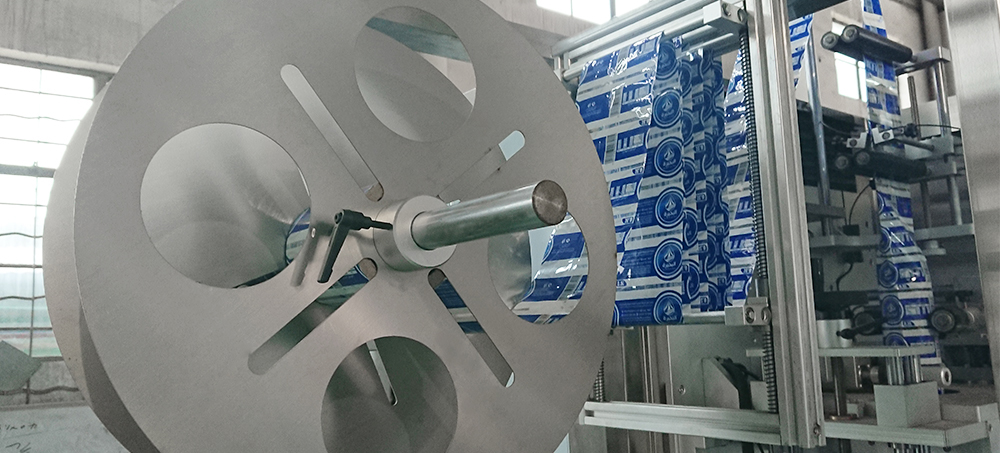

-Single shrink label feeding tray, microcomputer automatic control;

-Automatic detection, automatic positioning;

-Fast label change, labor-saving, accurate cutting position.

Parameters

| input power | 3KW |

| Input voltage | 220V/AC 50Hz |

| Productivity | 150 bottles/min (normal efficiency) |

| Host size | 2100L×850W×2000H |

| Applicable roll diameter | 28mm~120mm |

| Applicable label length | 30mm~250mm |

| Applicable label thickness | 0.03mm~0.13mm |

| Shrinkage way | Steam shrinkage or electrical shrinkage can be optional |

Details

Shrink Tunnel

1. Steam Shrink Tunnel

The steam ejection method is low-pressure steam injection, uniform distribution and seamless steel pipe design. The ejection outlet is divided into two adjustable sections. The height, front and rear, and air output of each section can be adjusted separately to achieve a perfect shrinkage effect.

| Input power | Single phase 220V 50HZ |

| Input power | 0.18KW |

| Dimensions | 1800L×550W×1500H |

| Weight | 200Kg |

2. Electrical Shrink Tunnel