Category: Beer Filling Machine

It is used for filling and sealing various kinds of glass bottles with crown type bottle mouth for beer filling production line. Apply double-evacuation process, adopts CO2 or nitrogen as counter pressure gas, no bottle no pre-evacuation & no fill. With filling, burst bottles flushing, high pressure bubbling, etc. The design is scientific and reasonable, operation and maintenance are convenient with high degree of automation. It is good choice for the beer production factory. For beer industry, there is Aluminum can beer and glass beer on the marketing. But the filling process is different. Can beer filling can’t do double-evacuation.

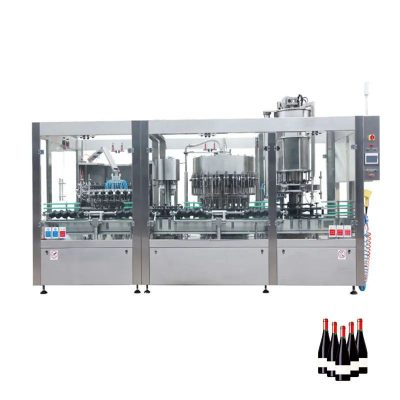

Wine/Liquor/Spirit Filling Machine

Mainly including bottle feeding, washing, rinser-filler-capper, water blowing, labeling, inner packing, carton packing, palletizing etc. Less space occupation and one operator needed for advanced rinser-filler-capper. The filler adopts mechanical valve or flowmeter E-valve to ensure the accurate filling; anti-dripping design avoids waste; safety design with negative pressure inside filling bowl head parts to prevent spirits escape.