Manual Beer Bottling & Canning Machines for Artisan Craft Brewers - IC Filling Systems

Our 4-4-1 Compactblock combines all phases of bottle filling in a single steel base unit , on wheels for flexible storage when not in operation. Bottle rinsing, Counter-pressure filling and closing with Crown corks. Ideal bottling equipment for artisan micro-breweries, wineries and small soft drinks producers.

Beer Bottling Machines & Canning Machines - IC Filling Systems

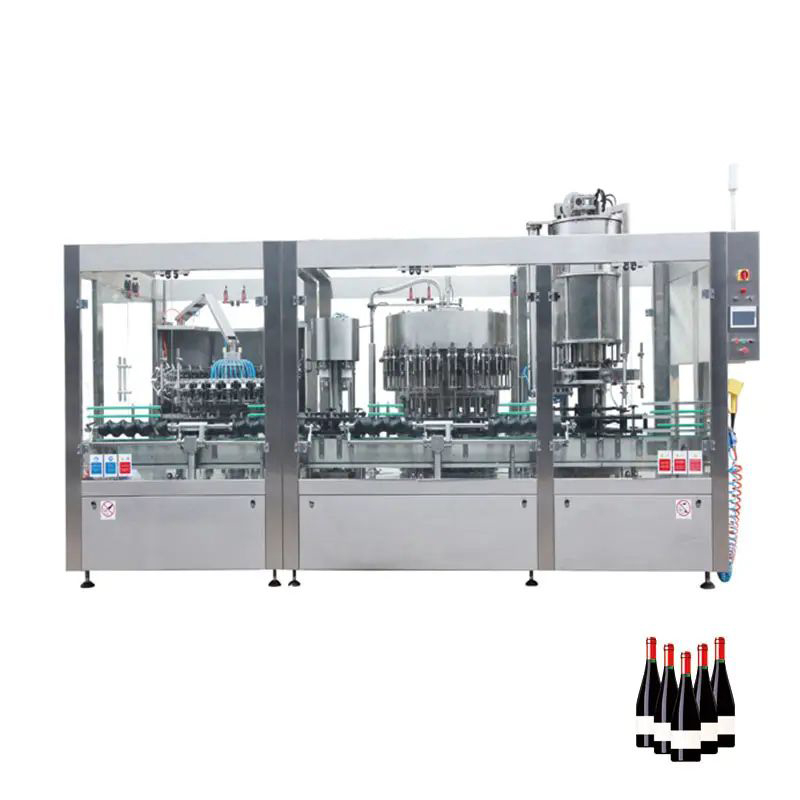

Our hybrid range can fill both bottles and cans. Automatic Beer Bottling Machines. Semi-Automatic or Manual Beer Bottling Machines. Automatic 12,000 cph Can Depalletiser. Automatic Beer Canning Machines at 3,000cph. Automatic Beer Canning Machines at 1,500cph. Automatic Beer Canning Machines at 850cph. Our beer bottling systems use stainless ...

Fillers | Beer Bottle Filling Machine | Criveller Group

Fillers. Developed to meet the needs of small wine producers, the manual/gravity filling machine has 4 or 6 filling spouts and is made entirely of AISI 304 STAINLESS STEEL. An optional pump with float can also be supplied. The filler has a height adjustable bottle rest tray, which allows accurate and fast level adjustment to accommodate the ...

IC Filling Systems

Bottling Canning Labelling & Packaging Equipment with Italian flair since 1994. IC Filling Systems have supplied bottling, canning, labelling, and packaging equipment for water, soft drinks, beers, wines, spirits, kombucha, food sauces, chemicals and toiletries since 1994. 29 years of focused experience. Ask us a question.

Canning and Bottling Beer: - Beverage Master

For breweries that are mid-size to large, choosing a machine with a 4,000 to 12,000 bottle per hour capacity is recommended. There are some important differences between bottle filling machines. Some bottling systems come with ¡°dummy bottles¡± and spray balls for cleaning. Some machines fill kegs in addition to bottles.

Machine and accessories for craft beer bottling | Tenco

Our vacuum filling machines are the perfect equipment to bottle the beer you¡¯ve brewed with passion. We offer a complete range of products to bottle beer: from bottling machines to labeling machines that allow you to easily cap and label your beer bottles. Our beer bottling solutions are easy and economical, perfect for small breweries and ...

Manual bottle filling | Sraml

With gravity-filling systems, the bottle is filled to the pre-set filling level by a simple fall. The system is designed to treat products with a temperature from ambient up to 90 ¡ãC (hot filling). Before being securely closed and sealed by SRAML CM, TSP-2002 and SA-CX bottle cappers, the bottles need to have caps placed manually.

Beer Filling Machine - Micet Group

Micet Group beer filling system uses stainless steel as the production material. Stainless steel is not easy to wear, and it is easy to clean. We can provide 4-head, 6-head, or 8-head beer filling equipment. This equipment is used in microbreweries, nano-brewery, and large breweries.

XpressFill Affordable Beer Bottle Filling Machine

The XF2500 / XF4500 uses the pressure in your tank to push the liquid into the bottle. As with our Level Fill fillers, the counter pressure / beer filler has sensor technology to stop the fill, leaving your bottles at a consistent height every time. XpressFill XF4500 4 Spout Counter Pressure Beer Bottle Filling Machine Setup and Operation.

Bottle Filling by ABE Equipment for Craft Beer, Spirits & Drinks

Automatic Bottle Filler for up to 33-85 BPM (based on 16.9 oz bottle) Rinsing and spraying consumes less than 1 GPM of water. Ultra uses 18 rinse valves, 18 fill heads, and 6 cap heads. Classic uses 8 rinse valves, 8 fill heads, and 4 cap heads. Learn More About Triumph Bottling Systems.

Contact Us Now