The labeling Machine is suitable for all kinds of cylindrical objects especially for small round bottles, such as glass bottles,plastic bottles. (The machine also can be customized for cone objects). Client can choose to add printer or code machine.It can work separately or connecting with conveyor.

HAW600 High Speed Horizontal Labeling Machine

Description

This is horizontal labeling machine which is suitable for bottles with small diameters such as ampoules, vials, hard tubes, etc. This machine is with a high speed of at least 300 bottles/min.

Features

1.The whole machine is made in SUS304 stainless steel and high grade aluminum alloy.

2.The labeling head adopts imported motor to assure labeling speed and accuracy.

3.The photo electricity and control system adopts advanced component from Germany or Japan or Taiwan.

4.Use PLC man-machine interface control system, which is easy to operate.

Parameters

| Labeling capacity | 6000-12000bottles/hour (Depending on label length and bottle thickness) |

| Height of Object | 25-90mm |

| Thickness of Object | 10-28mm |

| Height of Label | 20-90mm |

| Length of Label | 25-80mm |

| Label Roller Inside Diameter | 76mm |

| Label Roller Outside Diameter | 280mm |

| Power Supply | single 220V 50HZ 2KW |

| Machine size | 2700(L)×850(W)×1750(H)mm |

| Weight | 500Kg |

Details

Final product

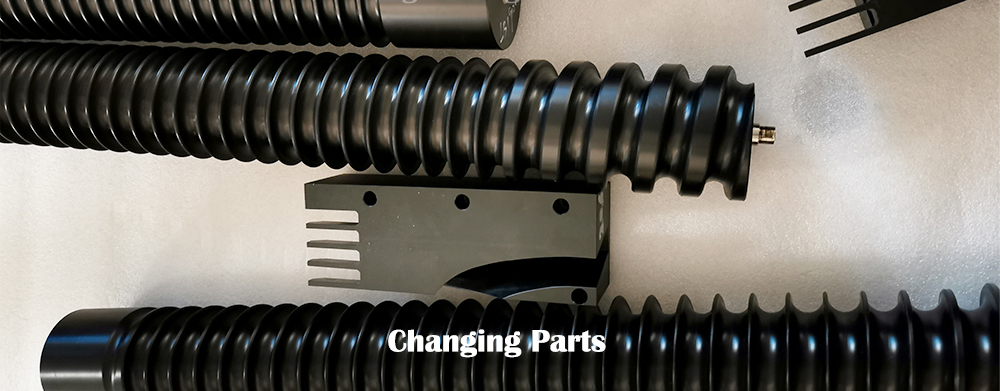

Changing parts

The changing part is the must when one labeler should be used for different sizes of ampoules or vials.

There are mainly two device of vertical and horizontal conversion: screw rod, turning device.

It takes some time to replace the changed parts. We recommend that one machine to be used for as few bottle types as possible, that would be better for high speed production.