This Essential oil filling machine line is widely suitable for small bottle filling and capping, made in SUS304 stainless steel or SUS316 anti-corrosion stainless steel for the part in contact with material, which is complied with GMP standard.

Essential Oil Filling Capping Labeling Machine Linear Line

1.Automatic Essential Oil Filling Machine line

Application:

This machine is applied for 15ml- 50ml essential oil filling capping and labeling line in plastic or glass bottles.

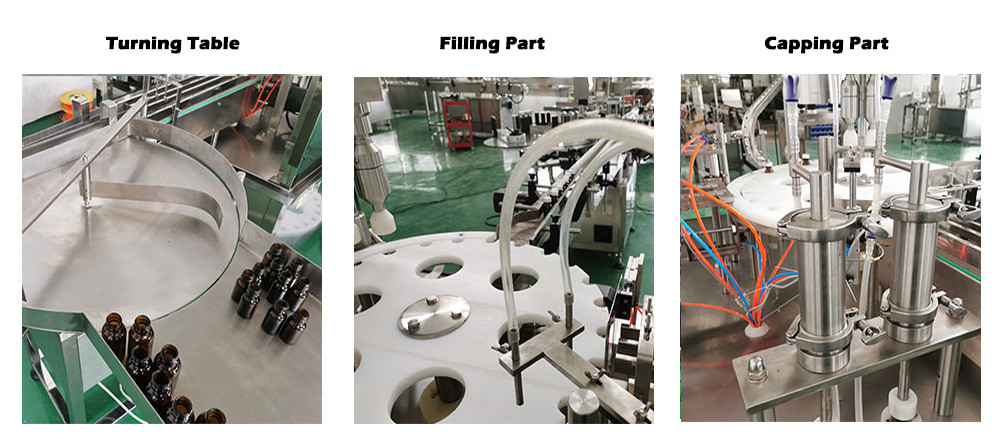

The machine can be customized to be completed with turn table feeder, several heads filler + capping system (dropper feeder + plugging + cap feeder + capper), labeling machine and turn table collector.

Features:

● There is high accuracy cam mechanism to provide Graduated dial to locate the cap on, accelerating cam transmission capping head lifting; constant torsion capping, mechanical pump dosing and filling; touch screen control, no bottle no filling, no inside and outside cap, with advantage of stable transmission, accurate location, accurate dosing, convenient operation etc.

● The equipment adopts four-row double-row piston pump to fill, and then is sent into the positioning dial by the conveyor belt, and the lid is rotated intermittently to enter the lid station to automatically cover the lid; the double-headed lid is used for sealing and the lid is four blades. Double-knife rolls down the edge with double-screw thread.

● This filling system is widely suitable for small bottle filling and capping, made in SUS304 stainless steel and SUS316 anti-corrosion stainless steel for the part in contact with material, which is complied with GMP standard.