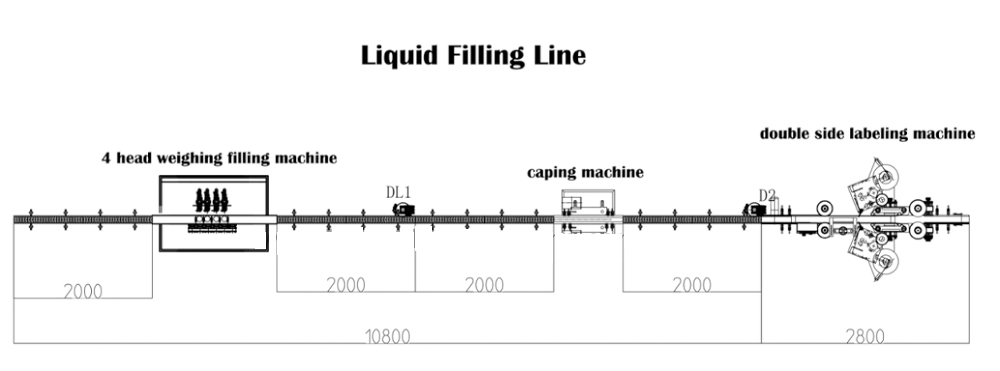

This Detergent Liquid Weighing Filling Line includes a big container filling machine, capping machine, and an automatic two side labeling machine. It can realize the whole process of automatic detergent filling to labeling for big filling quantity such as 5L, 10L, 20L or more. It can be used for round bottles, tubs, Jerrycans, etc.

Process:

4 heads Liquid weighing filling machine – automatic cap loader – automatic capping – double side labeling machine – output. (drawing is for reference only)

4 Heads Liquid Weighing Filling Machine

Description

Fully automatic in-line intelligent weighing and filling machine, which integrates mechanical, light, electricity and air, and is controlled by computer programs. It has various filling methods such as weighing type and volume type. Unparalleled filling accuracy and application range, not affected by various external factors such as material temperature, density, viscosity, gas content, etc., with high-precision weight detection, automatic barrel feeding, automatic peeling, automatic diving, automatic filling , Automatic promotion, automatic output. It can be widely used in various edible oils, lubricating oils, soy sauce vinegar, caramel pigments, syrup sugar alcohols, fruit wine, pesticides, daily chemicals, various sauces, chemicals, paints, coatings, resins and other industries.

Features

1. The whole machine is made of high-quality stainless steel, the part in contact with the liquid is made of PP material, and the explosion-proof self-priming pump is used.

2. Program control adopts PLC, man-machine interface (touch screen) operation

3. The weighing display adopts a large-screen instrument to directly set the filling amount, and the gross weight and net weight are freely set by the user.

4. Fast and slow double-speed filling, automatic tracking and correction of errors to ensure filling accuracy,

5. Inverter speed regulating linear filling, suitable for a wide range of containers.

Main technical parameter

| Items | Parameters |

| Suitable bottle size | According to sample, pls provide samples or size for checking |

| Filling volume | 10-50kg |

| Capacity | ≤450 barrels/hour |

| Air source | 0.4-0.8MPa |

| Air consumption | 120L/min |

| Power supply | 3phase, 380V/50Hz, 5kw |

| Total Weight | 300kg |

| Conveyor height | 400mm |

Automatic Capping Machine

Description

This machine is mainly a screwing device for large mouth bottle caps. It uses the rotation of the rubber wheel in the positive and negative directions to generate rotating friction force on the bottle cap. So as to complete the capping action. The device has no damage to the bottle cap, and the capping effect is obvious.

The frame of the whole machine is welded with 38*38 square tube, the panel is supported by t12Q235 board, and it is made of t1.2 stainless steel plate, plated support shaft, linear bearing.

Technical parameter

| Items | Parameters |

| Capacity | Abt. 2000 (bottles/hour) |

| Power supply | 3phase, 380V/50Hz, 1.5kw |

| Air pressure | 0.3-0.5 Mpa |

| Total Weight | 300kg |

| Dimension | 1000X850X1600 mm (Conveyor height: 400mm) |

| Cap feeding type | Vibration machine |

Double Side Labeling Machine

Features

1, It can make labeling on both top or side left or right side at the same time efficiently. Of course client can choose to make one side or double sides labeling.

2, Client can choose to add coding machine.

3, It can work separately or work connecting with conveyor.

4, Equipped with touch screen & PLC control system.

Technical parameter

| Items | Parameters |

| Labeling Speed | Max. 10 meter per minute. (conveyor speed) |

| Accuracy of Labeling | ±1mm (excluding object and label error) |

| Label roller inside diameter | 76mm |

| Label roller outside diameter | 320mm |

| Total Weight | 300kg |

| Dimension | 2800(L)*2000(W) (Conveyor height: 400mm) |

| Power supply | Single phase220V, 50Hz, 3.5kw |

| compressed air consumption | 5Kg/cm2 (if add the coding machine) |

Optional: CodingMachine

Ribbon coding machine can print numbers, letters, points, etc. Max. 3 lines, with over 100 free letter cubes.

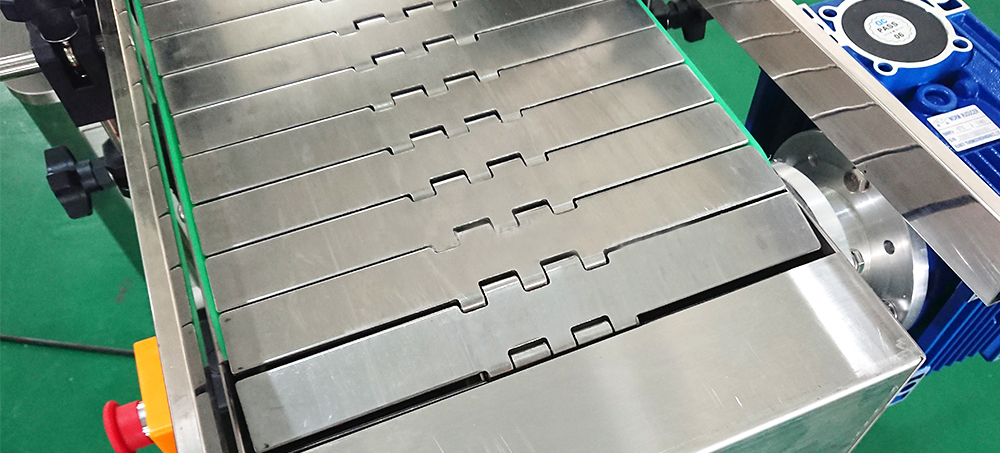

Connecting conveyor

Will adopt stainless steel for heavy product. Can be designed according to client’s requirements and layout.

Suitable products

*Example of some suitable products