Canning: Automatic 661 Can Filler & Can Seamer Machine for Beer, Cider, Wine, Soft drinks - IC Filling Systems

Specifications. We supply our automatic 661 EPV 6 valve machine with an automatic can rinser, filler, and seamer. Machines used for glass bottling can also be fitted to allow aluminium cans to be rinsed, filled and seamed. Simple canning for microbreweries and craft brewers at an economic price. Benefit of a SINGLE bottling unit for BOTH glass ...

EvoFILL Glass: Glass Bottle Machine | Sidel

Without compromising the performance of the line, EvoFILL Glass can now process a wide range of bottle sizes, beverage types, and filling temperatures: Fills CSD at ambient temperature. Beer filled up to 18¡ãC and CSD over 20¡ãC, with no need for a chilling unit. 48 to 192 filling valves. Level probe technology enables enhanced accuracy and ...

3000cph Automatic Canning Machine Canline 12-1 EPV - IC Filling Systems

Our innovative newly launched beverage counter-pressure can filler/seamer monoblock model: CANLINE 12-1 EPV is the first dual lane counter-pressure linear filler available on the market. This automatic counter-pressure filler/seamer monoblock is able to produce up to 3,000 x 330ml cans per hour output. You can handle different size cans with ...

Filling Machine for Beverages - Mitsubishi Heavy Industries, Ltd.

Filling machine for cans. A can is filled with a beverage and transferred to a cap seamer at high speed and then seamed with a cap. Our filler, the fastest in the world, can fill two thousand 350-ml cans per minute. The machine maintains a uniform filling volume by measuring the beverage content with an electromagnetic flowmeter before the ...

Automatic Craft Beer Carbonated Beverage Can Filling and Seaming Equipment - China Beer Filling Machine and Liquid Filling Machine

It is suitable for filling and capping carbonated beverage such as beer, CSD, etc. It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss.

Craft Beer Can Filling Machine - HZM Machinery

Product Features. 1. Beer can filling machine utilize the true counter-pressure-gravity filling technology to purge the can with fresh CO2 before filling, then fills the can gently by gravity, and then relieve the pressure in the can by Snifting CO2 from the can after filling. These functions help the beer can filling machine deliver low foam ...

24-24-8 Glass Bottle Beer Filling Machine - STM Packing Technology-Beverage Filling Machine Manufacturer

STM Packaging Tech 24-24-8 glass bottle beer filling machine help brewers control every aspect of the brewing process from tank temperatures, pressures and CO2 levels to bottle pre-evacuation, purging, fill rates and levels. All intelligently managed through an easy-to-use touch screen control panel. A complete beer production line solution from STM takes into account every step of your beer ...

Automatic 3 in 1 Monoblock Beer Bottle Filling Seaming Machine Production Line bottling filling machine glass bottle or can - flexfillingmachine

glass bottle or can 3 in1 Monoblock beer filling seaming machine After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Automatic Can Filling Machines | Craft Beverage Canning

X3 Series $28,000 + Shipping. Our simplified Hybrid can filling technology integrates counter pressure filling and atmospheric filling in an all in one easy to use canning machine. Simply Switch between counter pressure filling & atmospheric filling by the touch of a button. Whether you¡¯re new to canning or are gearing up for distribution, we ...

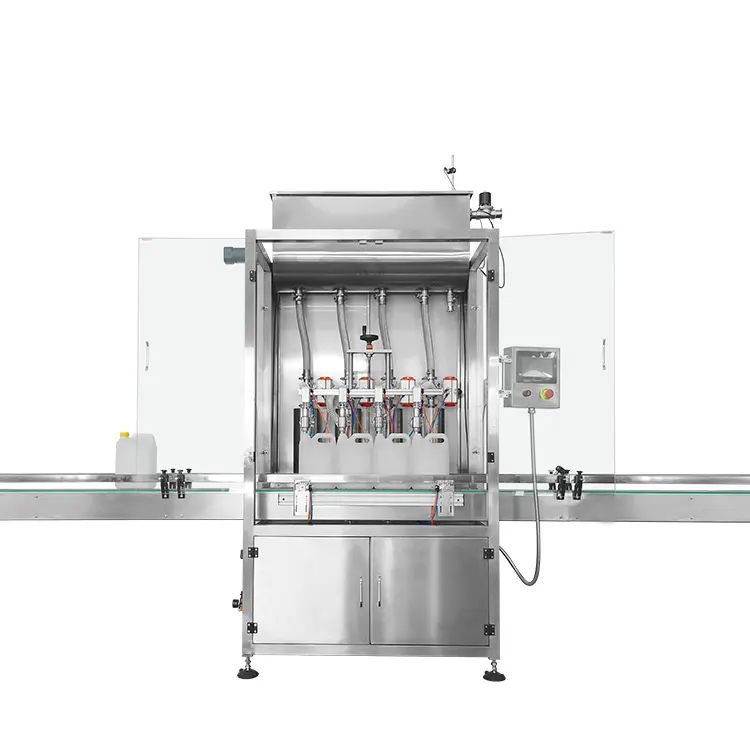

Automatic Glass Bottle Beer Filling Machine - PESTOPACK

The 3-in-1 beer bottle filling machine streamlines the beer bottling process by eliminating the need for separate machines for rinsing, filling, and capping. It offers advantages such as space-saving, improved efficiency, simplified operation, and reduced labor requirements. 3. Beer pasteurization tunnel:

Contact Us Now