CARBONATED BEVERAGE FILLING MACHINE - Your Bottled Water ...

Cola, juices, and sodas – The machine can smoothly fill these classic carbonated soft drinks while minimizing foaming. Sparkling water – The gentle filling process preserves the delicate carbonation in bubbly water, allowing production of plain or flavored varieties.

Carbonated soft drink filling machine - Comac

Sagitta 12-12-1 P is a carbonated soft drink filling machine able to fill up to 6,000 BPH. It is based on back-pressure filling technology and is designed to rinse the bottles with water or other disinfectant solutions, fill them with product and finally cap them.

Carbonated Beverage Can Filling Machine - HZM Machinery

Carbonated Beverage Can Filling Machine. Applicable : Carbonated Beverage, Beer, COLA, Soft Drink. Bottle : CANS, Bottles. Production Capacity : 4000~36000 Bottles Per Hour. Warranty : 24 Months. Price : Factory Direct Sales , Click The Button Below To Get Quote.

Carbonated Soft Drink (CSD) Filling Machine | HZM Beverage ...

A Carbonated Soft Drink (CSD) Filling Machine is a piece of equipment used in the beverage industry for filling carbonated soft drinks (such as sodas, colas, and other fizzy beverages) into containers like bottles or cans.

Carbonated Soft Drink (CSD) Filling Machine - SinoPAK

This cost-effective machine is ideal for washing, filling, and sealing bottled carbonated soft drinks. It features advanced technology for efficient filling, precise control, reliable capping, and minimal material loss. Additionally, it can integrate a long-distance control system. Model: DXGF 16-16-5.

Sparkling beverage carbonated soft drink filling machines

This type of machine is suitable for filling and sealing aluminum canned beer and carbonated soft drinks. It is equipped the advanced device, electrical equipment, and pneumatic control technology. It has the characteristics of filling repose fully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss.

Carbonated Soft Drink Filling Machine - SinoPAK

Model: DXGF 60-60-15. Capacity (BPH): 20000. Bottle Volume: 150ml to 2.5Ltr (Customized); Bottle diameter (mm): Dia50-Dia115mm; Bottle heighter: 160-320mm. Compress air pressure (Mpa): 0.3-0.4Mpa. Total powder: 9.5KW. Dimension (meter): 6.0*5.45*2.65M. Learn More. Inquire Now.

Carbonated Soft Drink Filling Machine | Aseptic Filling System

Carbonated Soft Drink Filling Machine. Brand: Newamstar. Rated 5.00 out of 5 based on 1 customer rating. ( 1 Review ) SKU: FILLINGSYSTEM-998569. Status: In stock. · Friendly HMI with easy switch for multi-languages. · Advanced reflection system by ceramic plate, heat-preservation system and heating system, preform can be heated evenly.

Bottle Filling Machines & Equipment – Filling Equipment ...

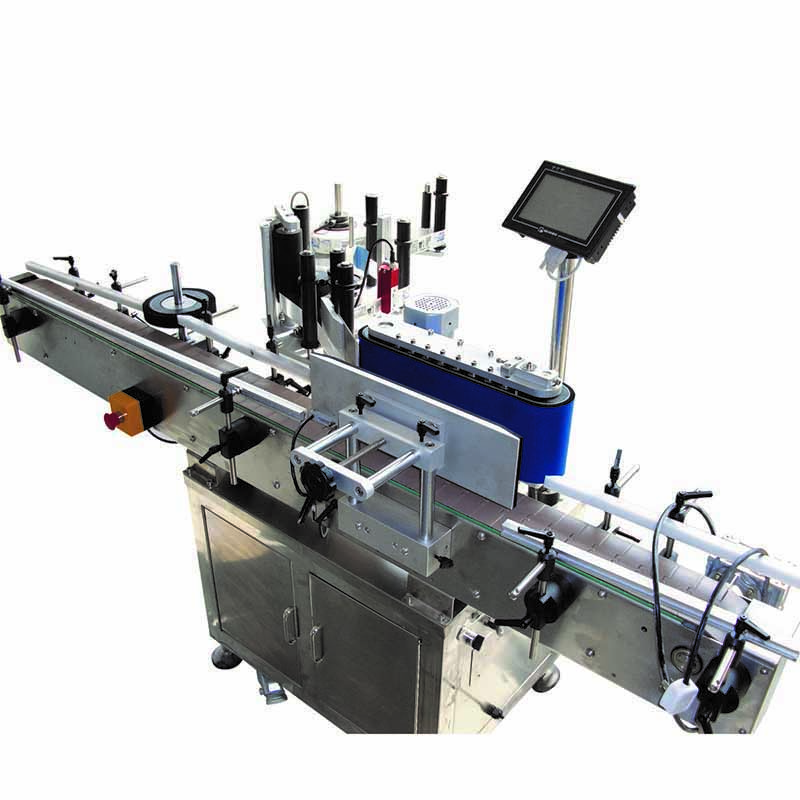

Search through our products of automatic straight line liquid fillers, bottling machine equipment, cosmetic filling equipment, filling equipment cappers, liquid filling machine and nozzles, piston fillers, rotary liquid filling machine, or wine & liquor fillers and the prices we offer.

Bottle Capping Machines & Equipment - E-PAK Machinery

Automatic spindle capping machines make the closing and sealing process quick and easy. Caps and bottles go through different matched disks, with every disk bringing in more torque until the cap is tight. Fully automated systems can reliably and consistently tighten caps for whole production lines.

Contact Us Now