Carbonated Soft Drink Filling Machine - SinoPAK

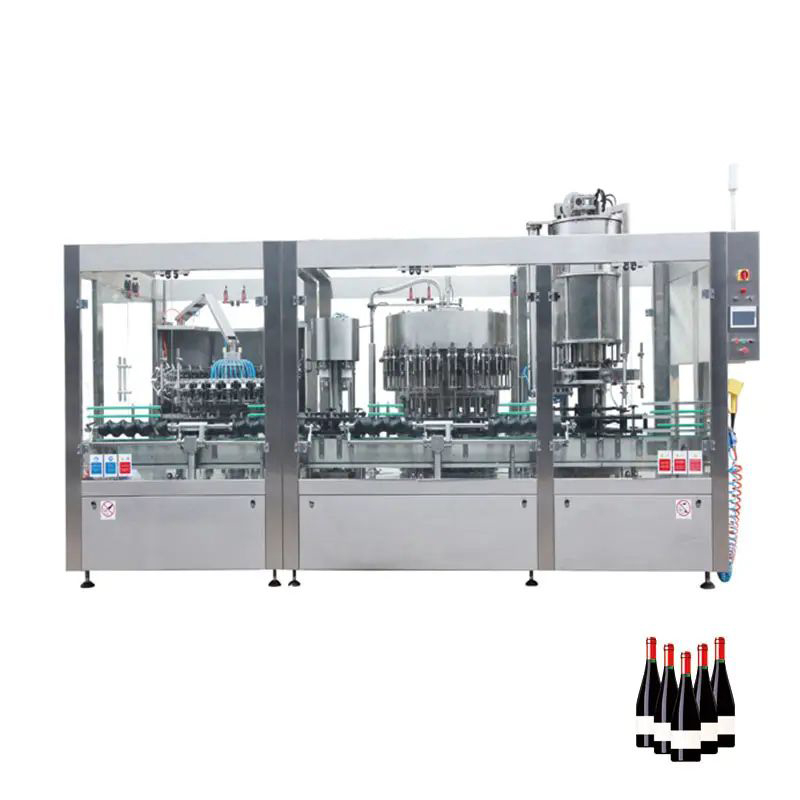

24000BPH DXGF72-72-18 CSD Sparkling Water Cola Carbonated Soft Drink Filling Line. The DXGF72-72-18 utilizes high-speed carbonated beverage filling valves for stable liquid inlet. It features bottle clamp technology to prevent pollution, ensuring calm filling, high speed, precise liquid level control, and reliable capping. Model: DXGF 72-72-18.

Carbonated Soft Drink (CSD) Filling Machine - SinoPak Machinery

This machine is cost-effective for carbonated soft drink production, offering advanced technology for efficient filling, precise control, and reliable sealing. It minimizes material loss and can integrate a long-distance control system. Model: DXGF 16-16-5. Capacity (BPH): 5000. Bottle Volume: 150ml to 2.5Ltr (Customized); Bottle diameter (mm ...

Carbonated Drink Filling Line ¨C New Crown Machinery

The initial discovery of carbonated drinks began from sparkling spring which is gushed from natural mineral water. With the development of technology, the Americans launched carbonated juice in 1807, adding juice in carbonated water for better taste, this product is very popular, and began the start of industrialized production.

Bottling lines for cans - Krones

Our portfolio comprises all machines from filling to pasteurisation, labelling to packing. Krones covers an extensive output range: from 10,000 to 130,000 cans per hour. As a systems supplier for the beverage industry, Krones also offers just the right can solutions.

4,000-15,000BPH Carbonated Soft Drink Can Filling Machine

Nearly 15 years, King Machine has provided bottling & packing equipments of liquid solutions to companies all over the world, water bottling line, juice filling line, carbonated soft drinks turnkey project, oil and soda water bottling line and labeling and packing ...

CSD (Carbonated Soft Drink) Filling Line - SinoPak Machinery

CSD 3 in 1 Filling Machine. View Details. It is mainly used for carbonated soft drink, such as cola, soda water and so on. The final filling temperature will be around 0-5¡æ. The machine design is shorten the time for the drink material contact with outside, increase the sanitation condition throughout economy benefit. Washing Part.

ProFill V Series Rotary Can Filler | Beverage Can Filling Machinery | TechniBlend

The ProFill rotary can filling and seaming lines are state-of-the-art, high-speed, mechanically controlled can filling systems designed around proven European True Counter-Pressure-Gravity filling technology and can seaming technology. As a beverage can filling system, the ProFill V series of volumetric can fillers runs at speeds up to 600 cans ...

Carbonated Beverage Bottling Equipment & Fillers | Busch Machinery

Busch Machinery offers full line carbonated beverage bottling equipment and fillers for cans and bottles at speeds ranging from 2,500 - 30,000 bottles per hour. The combinations of speeds and options are simply too numerous to list all on this website. Please call one of our sales engineers so that we can fit the right machinery for your needs.

Top Beverage Filling Machine Solutions | Sidel

Filling Sidel is able to fill your liquid products with the utmost precision and efficiency while handling the products smoothly and gently. Regardless of product type - from still water to carbonated soft drinks, beer, juice, isotonics, tea or liquid dairy products - we offer robust and reliable filling solutions along with extensive know-how and experience in filling:

The Ultimate Guide For Carbonated Beverage Filling Machines

Take, for instance, XYZ Machinery¡¯s 3-in-1 filling machine, a powerhouse handling both carbonated and non-carbonated drinks. Offering capacities from 3,000 to 30,000 bottles per hour, this machine is the epitome of automation and efficiency, providing a holistic solution for beverage production.

Contact Us Now