Water Fountain Bottle Filler - Water Refilling Station

BottleFillingStations: The #1 Resource For All Things Bottle Filling Station Related. Trusted by America's Top Government Agencies, Schools, and Companies.

Automatic Bottle Filling System using PLC - InstrumentationTools

Automatic Bottle Filling System is one of the example in PLC program using RSLOGIX 500. Table of Contents. Bottle Filling System. Problem Logic. Step Conditions: Start and Stop PB is used to start and stop the process. Start is pressed Conveyor starts moving until the Proximity Sensor is ON. Then solenoid valve is open for 5 seconds.

Bottle Filling PLC Ladder Logic - Automation Community

In this problem, write a PLC ladder logic for filling a bottle for 7 seconds based on a fixed time interval using timers.

PLC control system for bottle soft water manufacturing line ...

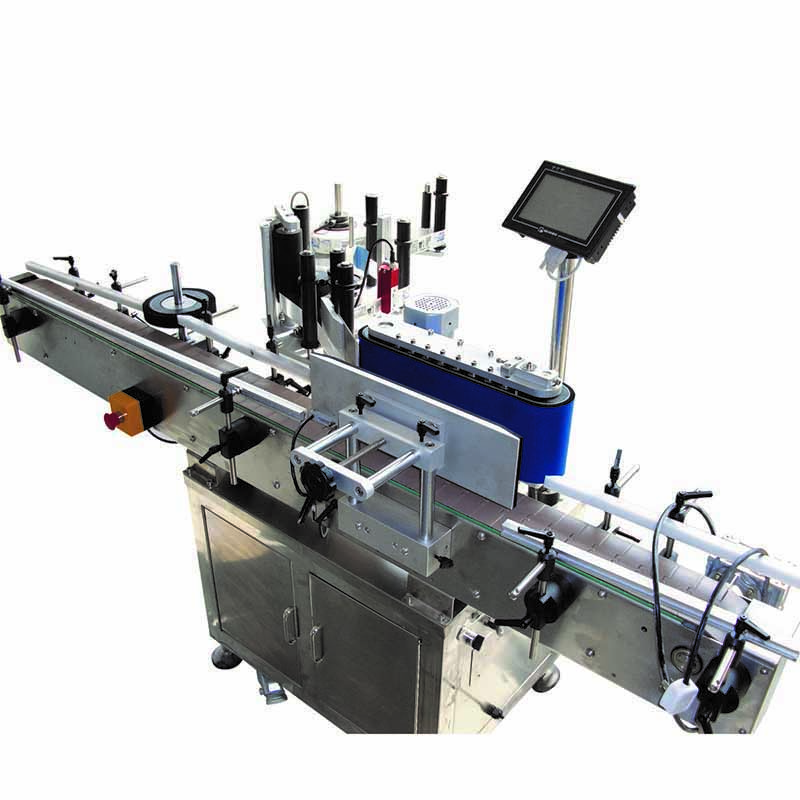

Advanced touch screen and PLC control system makes man-machine Water Bottling Plant (Bottled Liquid Filling Equipment water filling Line 2000bph) clients as the ideal bottling equipment for various soft beverage manufacturers.

Automatic Bottle Filling System Using PLC 101

In this project, the filling of the bottle is controlled by using a controller known as PLC which is also the heart of the entire system. For the conveyor system, a dc motor has been selected for better performance and ease of operation. A sensor has been used to detect the position of the bottle.

AUTOMATIC BOTTLE FILLING AND CAPPING SYSTEM USING PLC

The filling process is a mission performed by a machine that fills liquid products such as water or cold drinks. Traditional bottling methods include placing bottles on a conveyor belt and filling only one bottle at a time. In this project, we are implementing an “Automatic Bottle Filling and Capping” and are dedicating to the industries.

PLC Beverage Filling Line Design Improving Efficiency

PLC beverage filling line design can greatly improve efficiency by using photo sensors for empty bottle detection for waste detection.

PLC implementation of the bottle-filling application - EEP

In this example (see Figure 1), we will implement a control program that detects the position of a bottle via a limit switch, waits 0.5 seconds, and then fills the bottle until a photosensor detects a filled condition.

Applications of PLC Programming in Bottle Filling Process

This PLC program video explains the bottle-filling programming with simple steps. Inputs and Outputs. Digital Inputs: Start Push Button: I0.0. Filling Sensor: I0.1. Half Fill Sensor: I0.2. Stop Push Button: I0.3. Digital Outputs: Conveyor: Q0.0. Pump: Q0.1. Linear Actuator: Q0.2. Applications of PLC Programming. Program Description.

Automatic Bottle Filling System Using PLC Based Controller - CORE

Abstract. In this paper a bottle filling machine is introduced using Programmable Logic Controller (PLC) based controller in automation industry. The main aim of the paper is to design and fabricate a small and a simple filling system using PLC. The belt conveyor is used for moving the bottle.

PLC Based Automatic Bottle Filling and Capping System With ...

To develop an automatic bottle, filling and capping system with a deduction mechanism using sensors. Automatic filling process for all the bottles simultaneously

Contact Us Now