The 1-5L Engine Oil Filling Capping Machine is widely used for liquid filling in pharmaceutical, daily chemical, chemical, and other industries. It is filled with stainless steel dose pump and is suitable for different materials and different specifications. It has wide versatility.

Automatic Oil Filling Machine

Features

1. loading intelligent control: the touch screen directly inputs the filling amount, and the loading amount can be automatically calibrated. Switching between different specifications, the adjustment of the loading is extremely convenient, and there is no requirement for the level of the operator. Avoid the trouble of traditional side-by-side trials.

2. PLC intelligent control, with no bottle no filling, no bottle shutdown and other functions.

3. Special anti-drip filling head, better anti-drip effect.

4. The filling head is sprayed to the 2/3 position in the bottle to start filling, and the side is filled and raised to prevent the liquid from being shocked or splashed.

Parameters

| Items | Parameters |

| Production capacity | 20-50BPM |

| Air pressure | 0.6~0.8 MPa |

| Air consumption | 200L/Min |

| Power | Single phase 220V, 50hz, 1.2KW |

| Volume | 1, 3, 5 Liters |

| Filling nozzles | 8 |

| Machine Weight | 500kg |

| Machine Size L × W × H (mm) | 2400(L)×800(W)×1600(H)mm |

Details

Automatic Capping Machine

Description

coThe in-line capping machine comprises a capping unscrambler and a falling cover groove, a bottle clamping conveying mechanism and a capping wheel transmission mechanism. The bottle completes the action of scraping, glanding and capping during horizontal movement under the action of the bottle-carrying belt, and is suitable for the fitting of round caps and flat bottle (pot) screw caps of various materials. The whole machine has a simple structure and convenient adjustment. It is not necessary to exchange accessories when replacing the bottle type, as long as it is adjusted.

Features

1. The practical equipment is simple, stable, efficient and efficient

2. Wide versatility and economical machine

3. Automatic cap detecting and checking device is installed in the lid barrel, and the capping machine is automatically opened by the cap to ensure the supply of the cap.

4. The intelligent detection reverse cover and the high-speed electromagnetic valve are eliminated, effectively solving the problems of large noise, high gas consumption and low qualification rate, and the adjustment is convenient and fast

5. Automatic cap detecting and checking device is installed in the lid barrel, and the capping machine is automatically opened by the cap to ensure the supply of the cap.

6.Vibration Plate can feed caps one by one

Parameters

| Items | Parameters |

| Production capacity | 10-50BPM |

| Air pressure | 0.6~0.8 MPa |

| Air consumption | 200L/Min |

| Power Supply | 220V, 50hz, 2.0KW |

| Overall Dimension | 2000(L)×1500(W)×1800(H)mm |

| Weight | 700kg |

| Material | SUS304 |

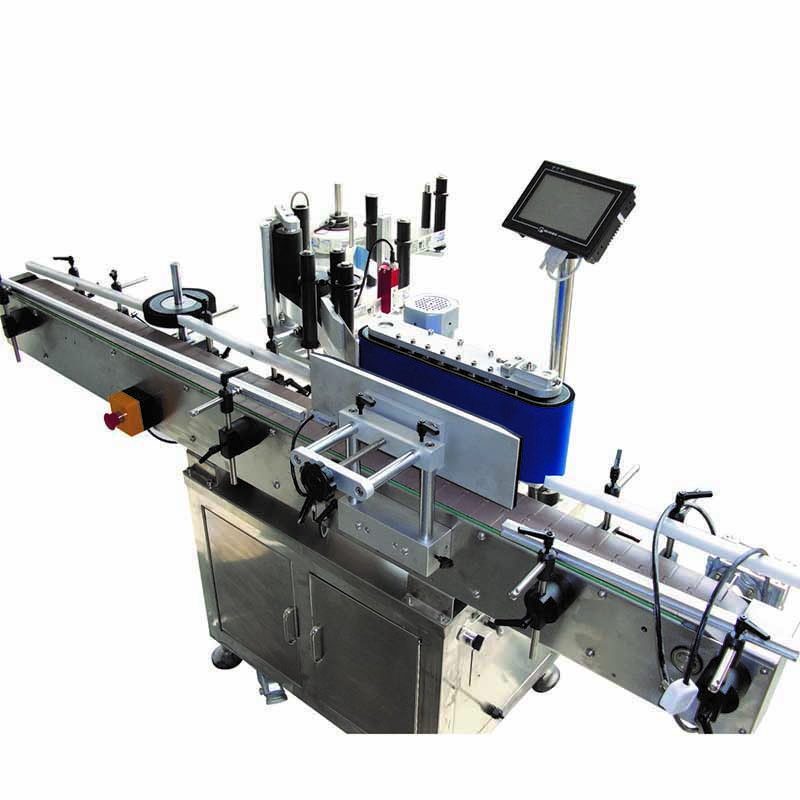

Automatic Sticker Labeling Machine

HAY200 Round Bottle Labeling Machine

HAS3500 Square/Flat Bottle Labeling Machine